From our CAD/CAM Programming to our computer controlled brakes, we offer the most complete State-of-the-Art equipment offer. With 3 fully-tooled turret presses and 2 lasers, our offerings include a vast number of shapes and sizes for custom assemblies. Our Robotic welders are complimented by our ASTM certified welders.Seiple Associates’ sheet metal capability is anchored by three computerized Amada turret punch presses and supported by a workforce highly competent in short run fabrication, specialty fabrication and quality control.

Forming on a variety of brakes, automatic stamping and tapping on CNC machinery, welding by hand or by Robotic, and the full gamut of related processes yields a virtually unlimited variety of parts to suit any design configuration. Parts are prepared for final finishing or plating as needed, cleaned and inspected.

Sheet Metal Fabrication

- Precision sheet metal fabrication using the latest technologies in metalworking, we are continually expanding and upgrading our own manufacturing processes to assure that we can offer the capability and capacity you are looking for.

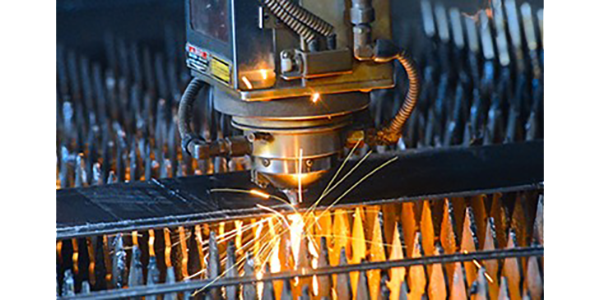

Laser Cutting

- Advantages: Precise, clean cutting and often does not require further processing. Ideal for carbon and stainless steel, sheet metal, and intricate patterns. A fast, repeatable and highly accurate process which is ideal for low and high production runs.

- Technology: A computer controlled high power laser beam is focused on the workpiece and the resulting heat energy melts or vaporizes the material. Any resulting molten material is blown away by pressurized gas during the cutting process creating a high quality edge.

Certified Welding

- Our sheet metal service is fully equipped with today’s latest equipment and techniques to meet our customer’s specifications. An appropriate welding quality system is the foundation of delivering a quality welded product or service. Utilizing our certified welders and inspectors assure that daily manufacturing operations are more consistent and traceable. This system also allows for new weld procedures to be written as necessary to meet specific customer requirements.