CNC Machining

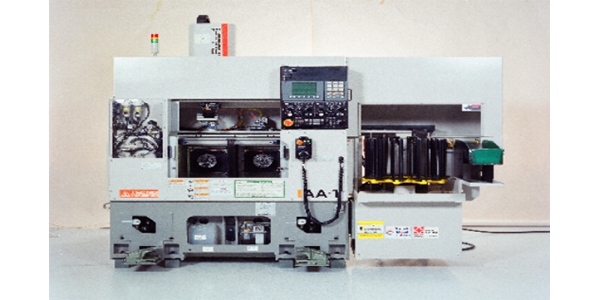

Utilizing the latest CNC turning, machining centers, arrays of multi-axis machining capabilities and state-of-the-art CAD/CAM software, we accurately accommodate many levels of precision and volume. We can produce complex parts with elaborate geometries and deep holes from even the most difficult to machine metals.

By combining the traditional values of service, quality, and performance, with versatility, flexibility, and advancing technology, Seiple Associates is able to find the manufacturing solution to meet your needs utilizing a full complement of 3, 4, and 5 axis CNC milling machines along with 4 axis Lathes.

Seiple Associates features a wide range of precision machining capabilities, including a full complement of computerized and manual milling and turning centers, as well as wire-EDM and water jet and laser cutting capabilities. Our CNC lathe machining capabilities offer small to very large capacities. The CNC lathes we use are custom configured for the most intricate applications and integrate with all of our CAD/CAM software systems. Our CNC machining department, equipped with CAD/CAM software, has the ability to download customer drawing files from anywhere in the world, greatly streamlining our machining processes. This has given us the ability to provide our customers with shorter turnaround times and a lower cost-per-piece than was possible with previous technology.

In addition to the CNC lathe capabilities offered to our customers, we also feature a robust offering of simultaneous 5-Axis machining and five-sided milling capabilities. These machines allow our customers to obtain parts with complex shapes and geometries at a competitive price point. This type of precision machining is also incredibly accurate, and provides a smooth surface finish when it is needed most.

CNC machining and all of the associated processes are completely programmed and run in house. We combine old-fashioned workmanship and strict, multi-stage quality control with the most up-to-date CAD/CAM and Robotic tools.

Machine tools are the muscle of Seiple Associates’ multiple capabilities, but our people are the heart and soul. The skill, know-how and attitude of our operators are essential. Talk with our machinists and feel the pride that influences their work. They’re a key reason we keep our promises to you!

EDM Machining

The ultimate in speed and precision, our EDM complement includes state-of-the-art Wire, RAM and Drilling.

Electrical discharge machining (EDM) machining is the process of creating a shape with electrical current discharges between two electrodes – the tool and the workpiece. Rapid electrical discharges pass between the tool and the workpiece, removing small amounts of material that is flushed away.

EDM services are effective at machining hard metals that may require intricate precision, as material hardness is not a factor. As the name suggests, electrical discharge machining is only applicable to materials that are electrically conductive. Seiple Associates offers multiple EDM services, categorized by the type of tool-electrode:

WIRE EDM SERVICES

A continuous strand of wire cuts with an intense electrical current, without inducing stress into the material.

- +/- 0.0001” typical tolerances.

- All electrically conductive materials.

SINKER EDM SERVICES

Custom-shaped electrode is lowered into material, to produce the negative or reverse shape of the electrode.

- +/- 0.0002” typical tolerances.

- All electrically conductive materials.

- Repair damaged holes or threads.

SMALL HOLE EDM DRILLING SERVICES

Brass or copper tubes are rotated while lowered into material, also called fast hole popping or micro hole drilling.

- +/- 0.001” typical tolerances.

- All electrically conductive materials

- Leaves burr-free hole.

Advantages of utilizing Seiple Associates’ EDM Services:

- Fast turnaround.

- Consistency.

- Achieve tight tolerances.

- Rapid prototyping.

- Small to large production runs.

- Performs well with Exotic Materials.

- Eliminates Heat Treat Distortion.

- Offers a Burr-free superior edge.

- Accomplish intricate contours.