What is additive manufacturing (3D printing)?

Additive manufacturing is a process of creating a three-dimensional object from a digital file. It is called additive because it generally involves building up thin layers of material, one by one. The technology can produce complex shapes that are not possible with traditional casting and machining methods, or subtractive techniques.

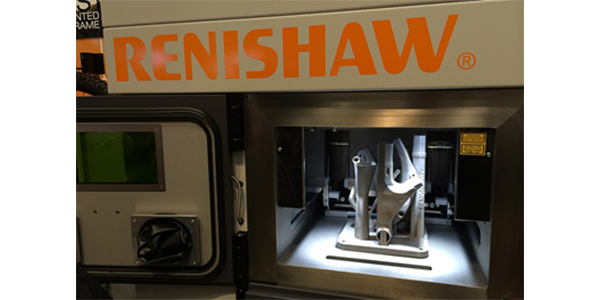

Direct Metal Laser Sintering (DMLS) is a 3D printing technology that uses metal powders and precision lasers to quickly and accurately create complex parts from a 3D CAD file.

Seiple Associates’ additive manufacturing systems can build in a range of metals, including titanium alloy Ti6Al4V, cobalt chromium, stainless steel, nickel alloys Inconel 625 and Inconel 718 and aluminum alloy AlSi10Mg.

Benefits

- Multiple part consolidation – the number of items in an assembly can be reduced by designing as a single complex component.

- Reduce tooling costs – parts can be manufactured directly without the need for tooling.

- Access to complex geometries – internal channels for conformal cooling, hidden features, thin walls and fine meshes.

- Freedom from restrictions associated with traditional subtractive and casting manufacturing methods – when combined with applying new design rules.

- Light-weighting – only build material where it is required for optimum weight reduction.

- Bespoke or customized items.

- Rapid design iterations right up to manufacture.

- Complementary tool – the additive manufacturing process can be integrated into current manufacturing processes to reduce steps, time to market and cost.

What is additive manufacturing (3D printing)?

Additive manufacturing is a process of creating a three-dimensional object from a digital file. It is called additive because it generally involves building up thin layers of material, one by one. The technology can produce complex shapes that are not possible with traditional casting and machining methods, or subtractive techniques.

Direct Metal Laser Sintering (DMLS) is a 3D printing technology that uses metal powders and precision lasers to quickly and accurately create complex parts from a 3D CAD file.

Seiple Associates’ additive manufacturing systems can build in a range of metals, including titanium alloy Ti6Al4V, cobalt chromium, stainless steel, nickel alloys Inconel 625 and Inconel 718 and aluminum alloy AlSi10Mg.

Benefits

- Multiple part consolidation – the number of items in an assembly can be reduced by designing as a single complex component.

- Reduce tooling costs – parts can be manufactured directly without the need for tooling.

- Access to complex geometries – internal channels for conformal cooling, hidden features, thin walls and fine meshes.

- Freedom from restrictions associated with traditional subtractive and casting manufacturing methods – when combined with applying new design rules.

- Light-weighting – only build material where it is required for optimum weight reduction.

- Bespoke or customized items.

- Rapid design iterations right up to manufacture.

- Complementary tool – the additive manufacturing process can be integrated into current manufacturing processes to reduce steps, time to market and cost.