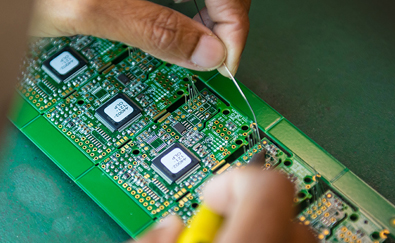

Among many of the Electronic services we perform are Surface Mount and Thru-Hole Technologies to assemble virtually any electronic requirement you may have. Our components are warehoused in a secure environment to guarantee your privacy is maintained. Quality assurance is performed through optical microscopes, X-Ray scanners, computerized CMM and comparators to make sure every part is to specification.

Among many of the Electronic services we perform are Surface Mount and Thru-Hole Technologies to assemble virtually any electronic requirement you may have. Our components are warehoused in a secure environment to guarantee your privacy is maintained. Quality assurance is performed through optical microscopes, X-Ray scanners, computerized CMM and comparators to make sure every part is to specification.

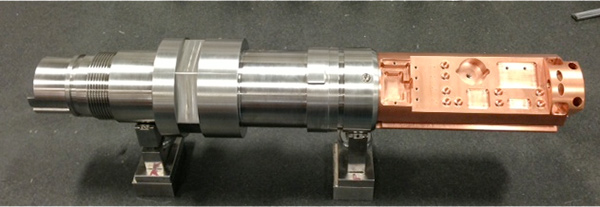

This Battery Assembly component is machined from Inconel 718 with a diameter of 5 ½” and overall length of 13”. After final machining and EDM operations this assembly has multiple priority components assembled to it from our secured warehoused facility and tested for final field readiness.

This Battery Assembly component is machined from Inconel 718 with a diameter of 5 ½” and overall length of 13”. After final machining and EDM operations this assembly has multiple priority components assembled to it from our secured warehoused facility and tested for final field readiness.

We specialize in smaller machined components as well with many being held to manufacturing tolerances of +/-.0001 for production runs. We machine all materials and run lot sizes from prototype to production runs of 10,000+. We offer warehousing to stock your “just in time” demands for virtually any production requirement.

We specialize in smaller machined components as well with many being held to manufacturing tolerances of +/-.0001 for production runs. We machine all materials and run lot sizes from prototype to production runs of 10,000+. We offer warehousing to stock your “just in time” demands for virtually any production requirement.

This is a multi material Top Sub component machined from Nitronic and Beryllium Copper with an approximate diameter of 4“ and an assembled length of 30”. Each half of this assembly is machined to tolerances of +/-.0002 and then pressed, pinned and welded to a final net shape with additional machining operations to final specifications.

This is a multi material Top Sub component machined from Nitronic and Beryllium Copper with an approximate diameter of 4“ and an assembled length of 30”. Each half of this assembly is machined to tolerances of +/-.0002 and then pressed, pinned and welded to a final net shape with additional machining operations to final specifications.

This Valve Body component is a machined part from Inconel 718 and its approximate size is 4 ¾” diameter with a length of 10”. Typical manufacturing tolerances for this part will be held to +/-.0002” and have multiple EDM operations performed as well.

This Valve Body component is a machined part from Inconel 718 and its approximate size is 4 ¾” diameter with a length of 10”. Typical manufacturing tolerances for this part will be held to +/-.0002” and have multiple EDM operations performed as well.

This stamped component is manufactured in house using a Progressive Die stamped out on a 300 Ton Minster Press. Material used for this part is a priority high strength alloy and the Progressive Die was constructed in house by our skilled Tool and Die Maker team.

This stamped component is manufactured in house using a Progressive Die stamped out on a 300 Ton Minster Press. Material used for this part is a priority high strength alloy and the Progressive Die was constructed in house by our skilled Tool and Die Maker team.